Moules et Outillages de Bourgogne specializing in the study, design and manufacture of tools for the investment casting and the injection of wax models is now equipped with all the technologies enabling reverse engineering of a part to reproduce.

The example below details all the steps necessary for this process.

Each step is obviously achievable independently of the others, if a client wishes for example to recover a usable digital file and modify it without going as far as 3D printing of it.

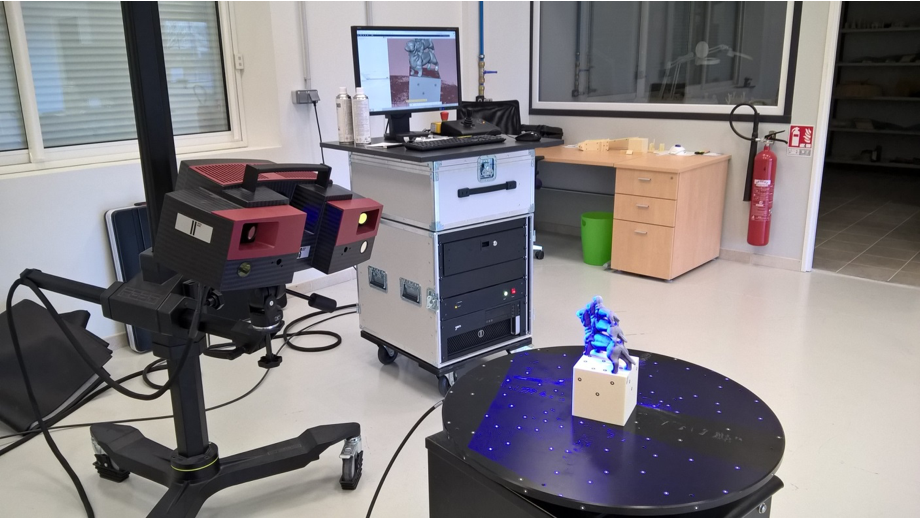

STEP 1: Data acquisition, with GOM ATOS II triple scan scanner.

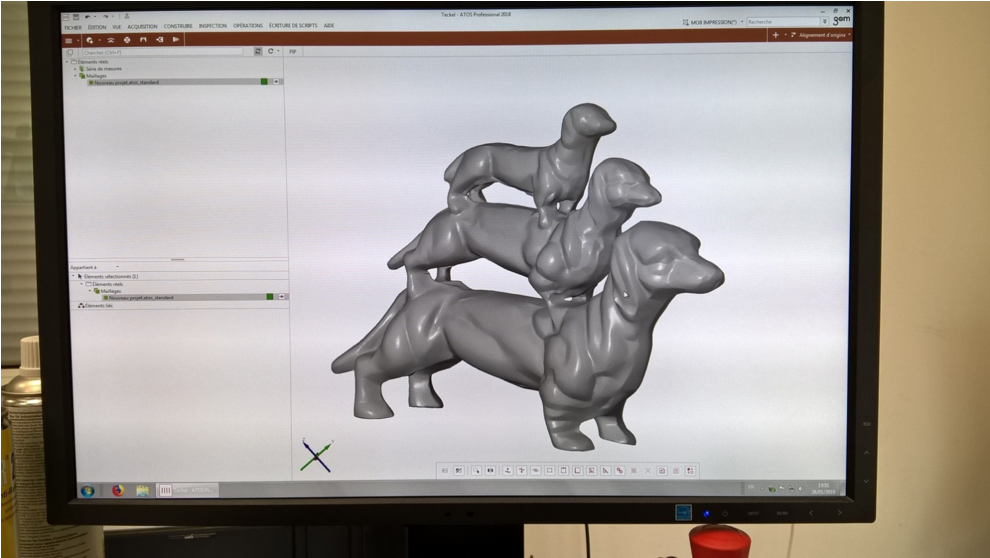

STEP 2: Cleaning of the mesh, to obtain a closed surface which can be used by the printer.

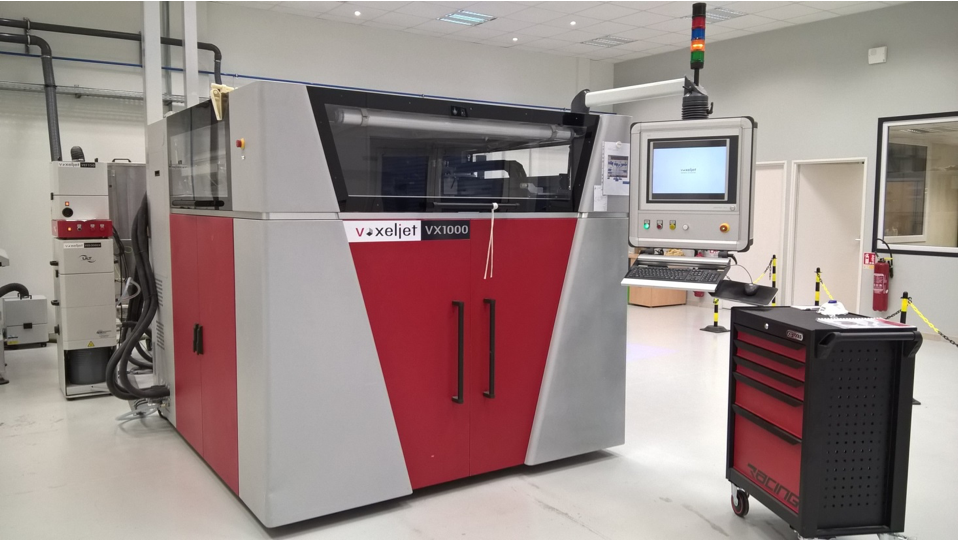

STEP 3: Printing with a VOXELJET VX1000 printer

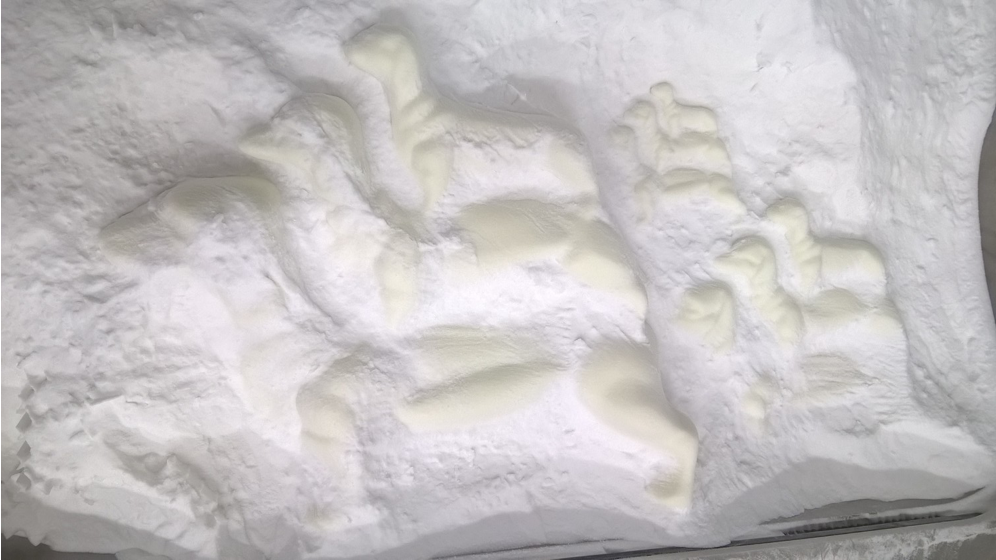

STEP 4: Powder removing, cleaning.

STEP 5: Comparison with the original